- BAKERY & DAIRY

Depositors

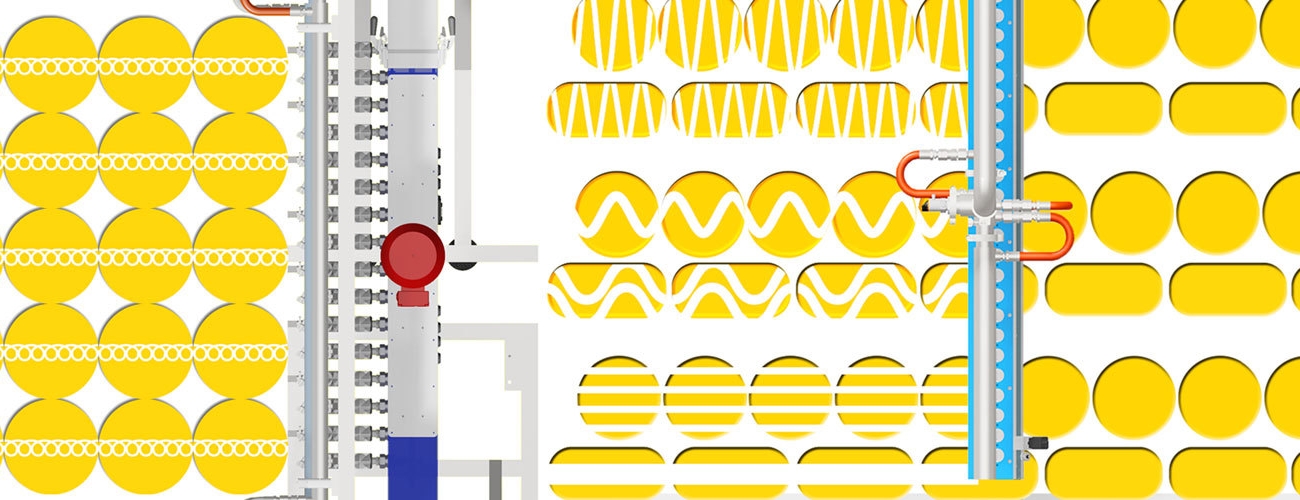

- Cake Depositing System (CDS)

- Extrusion Manifolds

- Laminar Flow Manifold: Extrusion

- Laminar Flow Manifold: Cake

- Laminar Flow Manifold: Sheet Cake

- Marshmallow Depositor

- Overhead Servo Creme & Jelly Injector (Contained Pan)

- Servo Cake Depositor

- Servo Creme & Jelly Injector (Free Pan)

- Servo Oven Band Depositor

LAB TESTING AT OAKES

Oakes is dedicated to meeting the research and development requirements of our customers with in-house lab testing...

Learn More - CHEMICAL & LATEX

LAB TESTING SERVICES

Oakes is dedicated to meeting the R&D requirements of our chemical foaming customers with scalable lab testing...

Learn More - SERVICES

- INSIDE OAKES

- NEWS

- CONTACT